19 Dec Designing for compliance

In this article for Fire Middle East, Len Swantek, Director of Global Compliance, Victaulic explains how, as a global leader in the design and manufacture of fire safety products and systems, the company is sharing its knowledge and experience with today’s engineering and technology students, who will one day play a key role in the development of these life-safety systems… Bringing real word problem solving to the classroom.

Through our participation in various academic programmes, we became keenly aware of the need to share knowledge on the regulatory process; a uniquely relevant subject that fire protection engineering students will encounter throughout their future careers. While some universities have technical curriculum focused on fire protection system design and the related building codes, the absence of specific coursework dealing with product testing and agency certification was a glaring need that we view as a critical element in fire protection engineering.

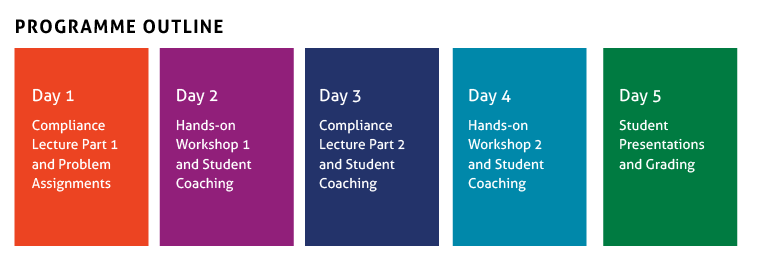

This led to the launch of Victaulic’s Regulatory Compliance Workshop in 2018. The programme includes an in-class lecture focused on Designing for Compliance, which highlights the importance of integrating the individual performance requirements from the fire codes and agency test standards throughout each step in the product development process. The lecture is followed by discussion and the distribution of problem assignments to teams of up to six students. Each team works together to solve real-world fire industry problem scenarios. While some of the workshops are organised to create a spirit of competition, the primary objective is to provide the students with a hands-on experience that they can build-on throughout their remaining studies. The student teams have a fixed time period (typically 4-5 days) to develop a complete technical solution and professional presentation that will be judged by the instructors and graded by the university faculty.

Industry scenarios

The individual problem scenarios are carefully constructed to represent real-world industry situations, albeit with fictional characters and titles, building names and site locations. Some problem scenarios contain conflict between opposing parties, and may include such factors as a product malfunction, code violation or system design problem. Additional factors include commercial considerations, legal ramifications, time constraints and the associated deadlines that are common in any building construction or retrofit project. Each scenario is drafted and built around a particular product or fire system application. Once the problem framework is established, the instructors layer-in a wide range of information that is either critically important to the development of a technical solution or multiple solutions, as well as other details that can be purposely extraneous and have absolutely no impact what-so-ever on the final outcome. It is the student teams’ objective to sift through the details and determine how the information is either relevant and technically valuable in developing their solution, or if additional information and research may be necessary in order to fully develop and test their conclusions.

One of the most popular problem scenarios involves trouble-shooting a system-related malfunction. This is where the students must have completed specific engineering and/or fire safety coursework in their previous studies and possess a sufficient understanding of fire protection system design and operation. They are presented with a specific product model along with details of the malfunction that has been allegedly reported by the building owner or the local fire inspection authority.

Technical evaluation

During the hands-on workshop sessions, the students have access to the actual product described in the scenario, along with all the tools, measuring instruments and gauges that are necessary to disassemble the product and conduct their analysis. The students are required to follow the manufacturer’s manuals and carefully dissect each sub-assembly, measure critical components, conduct research, select alternate materials, or even create a new design if that is what the team determines to be required in order to solve the problem.

The manufacturer’s product data sheets, electrical schematics, along with installation and operation manuals, agency test standards and regional fire codes are provided to assist the students in their product and system evaluations. Throughout this part of the workshop, the students must record critical dimensions and note all observations and assumptions. They are encouraged to take photographs, use internet resources in their research and work collaboratively together to develop a complete and final solution. If the student team determines several possible root causes and corrective actions, they are required to prioritise their conclusions and include all information in their final presentation.

Adding pressure

Because the scenarios are based on actual industry events, there are commercial and legal ramifications included to provide a sense of urgency and add a level of pressure for the student teams, who will someday be faced with very similar situations in their full-time fire protection careers. Such conditions include claims for liquidated damages, financial penalties and back-charges for system shutdowns, repair and/or retrofit. As each team member assumes a unique role in the scenario, the ensuing debates between the building owner, fire protection system designer, installation contractor, code enforcement officer, product manufacturer and their suppliers all add to the real-world feel of the classroom discussions. These debates often sound vividly real as though we are all working at an active jobsite trying to resolve a time-sensitive problem for the building owner and their tenants.

The Victaulic instructors also play the role of various involved parties for the purpose of challenging the students on their assumptions and methodology. This is where the students can also demonstrate their technical skills as well as engineering leadership and confidence in dealing with stressful situations. During our office hours, we provide coaching and advice to each team to ensure the most rewarding experience for everyone.

Final presentations

On the final day of the workshop, each student team presents their problem resolution in full detail, restating the original problem scenario, outlining their assumptions and problem-solving methodology, presenting dimensional and other data and stating a final conclusion and recommendations for corrective action. Where financial or legal obligations were of concern, the students must carefully address how their proposed solution will either reduce or eliminate future occurrences and how the financial obligations will be satisfied through negotiations with all parties involved. Interestingly, we find that these future fire protection engineers often reach amicable solutions much faster and with less strain than their real-world professional counterparts.

The Regulatory Compliance Workshop has been extremely successful in combining theory and practical hands-on experience with actual fire systems and components that the students can utilize in building successful and rewarding careers in the global fire safety industry. There are plans to extend the Regulatory Workshop in 2023 to other universities who currently offer a fire-safety engineering curriculum.

Sorry, the comment form is closed at this time.